Asbestos is an inexpensive, naturally occurring mineral. Before the public knew it caused mesothelioma cancer, asbestos had a good reputation among American builders and manufacturers.

The mineral could be mixed into a wide range of materials to increase their strength and heat resistance. The asbestos industry covered up the risks of asbestos exposure for many years so it could profit off the mineral.

The height of asbestos use in America took place from the 1930s to the 1970s. After thousands of sickened workers began filing mesothelioma lawsuits, American companies largely phased out the use of asbestos in the 1980s.

Asbestos is not banned in the United States, even though it is in most developed nations. Asbestos-containing products remain very popular in countries such as Russia, China and India.

Asbestos is dangerous when it gets into the air as dust. Whenever raw asbestos is mined or processed — or an asbestos-containing material is mixed, cut or crushed — everyone nearby is at risk of breathing in microscopic asbestos fibers.

Toxic exposure can happen anytime an asbestos-containing material is disturbed. But most asbestos-related illnesses develop because of long-term occupational exposure. Certain asbestos products are especially prone to releasing toxic dust.

In addition to causing mesothelioma, asbestos exposure is also known to cause all forms of lung cancer. Asbestos-related lung cancer accounts for approximately 4% of all lung cancer cases in the U.S.

Asbestos Cement

Asbestos cement is cheap and durable. Sold premade in flat or corrugated sheets, it was a popular choice for simple floors, walls and roofs. Workers and sailors also used asbestos cement to insulate and repair high-temperature machinery such as boilers.

Mixing asbestos cement sends high levels of toxic dust into the air. This was a major problem on Navy ships, where asbestos dust would become concentrated in rooms where sailors lived, worked and slept.

Once asbestos cement is set, it generally keeps toxic mineral fibers contained. But as soon as the cement is demolished or destroyed, it becomes a major exposure risk again.

Common Brands of Asbestos Cement Products

- Ambler (by Keasby & Mattison)

- Armatemp (by AC&S)

- Asbestone

- Atlas

- Caltemp (by Fibreboard)

- Careystone (by Celotex)

- CertainTeed

- Combustion Engineering

- Eternit

- Flintkote

- Garlock

- Gold Bond (by National Gypsum)

- James Hardie

- Owens-Corning Fiberglass

- Philip Carey

- Pittsburgh Corning

- Plibrico

- Quik-Set (by Foster Wheeler)

- Ruberoid (by GAF)

- Super 66 (by Eagle-Picher)

- Thermalite (by Keene)

- Transite (by Johns-Manville)

- U.S. Gypsum

- Unarco

- W.R. Grace

Asbestos Pipe Wrap and Block Insulation

The lightweight and heat-resistant properties of asbestos make it an effective insulator. A common type of pipe wrap insulation was made out of asbestos cardboard. Blocks of nearly pure, processed asbestos were also fixed to pipes and walls as insulation.

Because these materials are so lightweight, they are very easy to damage. When a material can be crumbled by hand pressure, it is called a friable material. Friable asbestos materials are the most dangerous because they can release toxic dust at the slightest disturbance.

Manufacturing, installing, repairing and removing friable asbestos insulation are all very dangerous. Asbestos insulation products typically become more friable as they degrade over time.

Asbestos insulation was standard in almost all construction projects during the middle of the 20th century.

Common Brands of Asbestos Pipe and Block Insulation Products

- Air Cell (by Johns-Manville)

- Armstrong Contracting and Supply

- Careytemp (by Celotex)

- CertainTeed

- Combustion Engineering

- Crown Cork and Seal

- Ehret Magnesia

- Flintkote

- GAF

- Gold Bond (by National Gypsum)

- Hy-Temp (by Nicolet)

- Owens Corning

- Owens-Illinois

- Rock Wool Manufacturing

- Super 66 (by Eagle-Picher)

- Thermobestos (by Johns-Manville)

- Unarco

- Unibestos (by Pittsburgh Corning)

Asbestos Gaskets

Asbestos gaskets were once standard for joining and sealing high-temperature machine parts. These products could take the form of pure asbestos rope, cutout sheets of asbestos or asbestos interwoven with layers of metal.

Manufacturing and installing these gaskets involved mixing and cutting pure asbestos. Removing old asbestos gaskets was just as hazardous, because ripping and scraping them releases large amounts of toxic dust.

Asbestos gaskets were commonly used in factories, refineries and a variety of vehicle engines.

Common Brands of Asbestos Gasket Products

- Chempro (by Chemical & Power Products)

- Durabla

- Flexitallic

- Garlock

- Goetzerit (by Goetze Gasket and Packing)

- Goodyear

- John Crane

- Johns-Manville

- McCord

- Melbesto (by Melrath Supply and Gasket)

- Palmetto (by Greene, Tweet & Company)

- Raybestos-Manhattan

- Tauril (by Anchor Packing)

Spray-on Asbestos Insulation

Spray-on products — such as popcorn ceiling treatments and fireproofing for steel beams — were one of the first categories of asbestos materials regulated by the government. This is because spraying asbestos into the air, where it can be easily inhaled, leads to high levels of exposure.

Even once applied, spray-on products usually remain friable. This means they can easily release toxic dust when scraped off during a renovation project.

Spray-on asbestos products were common in many construction projects, large and small.

Common Brands of Spray-on Asbestos Products

- K-Spray (by Kaiser Gypsum)

- Limpet Asbestos (by Keasbey & Mattison)

- Limpet Spray (by Turner & Newall)

- Monokote (by W.R. Grace)

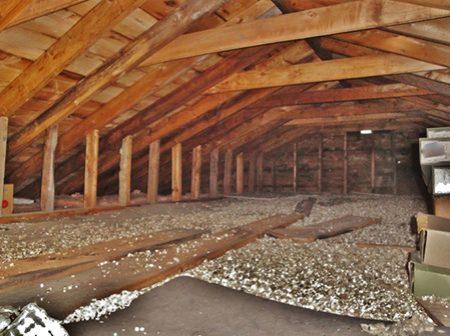

Asbestos-Containing Attic Insulation

Vermiculite attic insulation is made out of little pebbles that become very light when processed. Vermiculite on its own is harmless, but unfortunately most of the vermiculite used to make Zonolite-brand attic insulation came from mines contaminated with asbestos.

The vermiculite mines in Montana and the network of Zonolite processing facilities spread across America were notorious sources of asbestos exposure. Contaminated vermiculite remains in many homes today, still posing a hazard to anyone who disturbs it.

Other asbestos products include:

- Molded plastic electrical components

- Vinyl tiles and flooring

- Ceiling tiles and acoustic insulation

- Construction adhesives and sealants

- Shingles and flat-top roofing

- Automobile brake linings

- Felt sheets used at paper mills

- Fireproof gloves and suits

- Filters for gas masks and cigarettes

- Decorative fake snow